- Contact:+86 13699268391 Email:info@hb-xt.com

- Chinese

Product

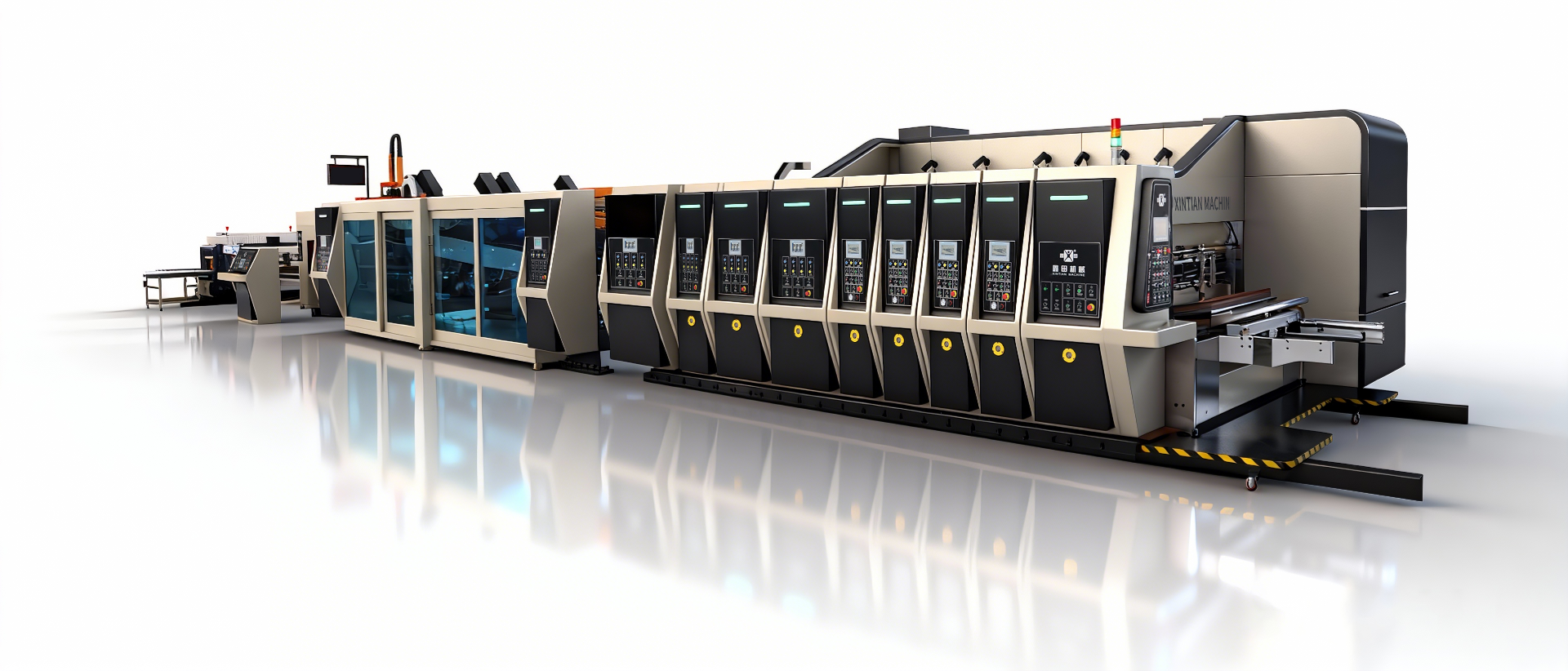

XT-S Series

XT-S Series

Function and Characteristics:

■ The electrical appliances and computer software of the whole machine adopt internationally renowned brands, with stable and reliable quality.

Man-machine interface, computer order management, convenient operation, and more blocks for changing orders.

■ Quickly judge and solve equipment faults through network remote maintenance.

■ The whole machine is designed and manufactured according to high performance and high safety, and meets the acceptance of European CE standards.

■ Servo pressure-free leading edge paper feeding (invention patent number: ZL 20141077672.3), which realizes pressure-free paper feeding, has zero pressure on the cardboard and improves the compression resistance of the carton; Compared with the traditional mechanical gearbox mechanism, servo drive is more durable and can feed paper accurately for a long time.

■ The important parts of the whole machine are aged and tempered to eliminate the internal stress of metal; It is made by high-precision machining center and grinded by CNC grinder.

■ The shaft and roller of the whole machine are made of high-quality steel, tempered, quenched and tempered, ground, high-precision computer dynamic balance correction, and the surface is plated with hard chromium.

■ The transmission gear of the whole machine is made of high-quality alloy steel, carburized and quenched, and after grinding, the color registration accuracy is high after long-term use.

■ The transmission part of the whole machine adopts keyless connection, and the connection gap is zero jump, which is suitable for long-term high-speed operation with large torque.

■ Each unit is equipped with an automatic oil balancer to ensure the oil balance in each unit oil tank is consistent.

■ The printing unit adopts vacuum adsorption paper feeding device to ensure the printing effect of the whole page and the paper feeding accuracy of deformed cardboard (roller paper guide and adsorption synchronous transmission structure can be added).

■ The important transmission parts of the whole machine adopt reinforced self-aligning bearings, which have long service life and convenient maintenance, ensuring long-term and high-speed operation of the equipment.

■ The main motor adopts frequency conversion motor, which is energy-saving and stable to start, with motor starting protection device.

■ Unique production image processing device, which can watch the working situation of the rear in front of the machine.

■ Novel status indicator lamp, the startup status indicates the working status and fault information of the machine.

■ The clearance adjustment of the whole machine uses dual-purpose functions of electric adjustment and computer adjustment.

■ Standard LED speed and production quantity display screen.

■ The electrical appliances and computer software of the whole machine adopt internationally renowned brands, with stable and reliable quality.

Man-machine interface, computer order management, convenient operation, and more blocks for changing orders.

■ Quickly judge and solve equipment faults through network remote maintenance.

■ The whole machine is designed and manufactured according to high performance and high safety, and meets the acceptance of European CE standards.

■ Servo pressure-free leading edge paper feeding (invention patent number: ZL 20141077672.3), which realizes pressure-free paper feeding, has zero pressure on the cardboard and improves the compression resistance of the carton; Compared with the traditional mechanical gearbox mechanism, servo drive is more durable and can feed paper accurately for a long time.

■ The important parts of the whole machine are aged and tempered to eliminate the internal stress of metal; It is made by high-precision machining center and grinded by CNC grinder.

■ The shaft and roller of the whole machine are made of high-quality steel, tempered, quenched and tempered, ground, high-precision computer dynamic balance correction, and the surface is plated with hard chromium.

■ The transmission gear of the whole machine is made of high-quality alloy steel, carburized and quenched, and after grinding, the color registration accuracy is high after long-term use.

■ The transmission part of the whole machine adopts keyless connection, and the connection gap is zero jump, which is suitable for long-term high-speed operation with large torque.

■ Each unit is equipped with an automatic oil balancer to ensure the oil balance in each unit oil tank is consistent.

■ The printing unit adopts vacuum adsorption paper feeding device to ensure the printing effect of the whole page and the paper feeding accuracy of deformed cardboard (roller paper guide and adsorption synchronous transmission structure can be added).

■ The important transmission parts of the whole machine adopt reinforced self-aligning bearings, which have long service life and convenient maintenance, ensuring long-term and high-speed operation of the equipment.

■ The main motor adopts frequency conversion motor, which is energy-saving and stable to start, with motor starting protection device.

■ Unique production image processing device, which can watch the working situation of the rear in front of the machine.

■ Novel status indicator lamp, the startup status indicates the working status and fault information of the machine.

■ The clearance adjustment of the whole machine uses dual-purpose functions of electric adjustment and computer adjustment.

■ Standard LED speed and production quantity display screen.

Product Details

Main technical parameters

| SERIAL | WYAZS NAME | UNIT | WYAZS | ||

| 900×2000(Φ304) | 1200×2000/2400(Φ420) | 1600×2400/2800(Φ536) | |||

| 1 | Inboard width size | mm | 2600 | 3000 | 3400 |

| 2 | Max.paper size | mm | 950×2200 | 1270×2600 | 1670×3000 |

| 3 | Max.printing size | mm | 900×2000 | 1200×2400 | 1600×2800 |

| 4 | Skipfeeding size | mm | 1150×2200 | 1500×2600 | 1850×3000 |

| 5 | Minfinish size | mm | 290×640 | 320×72 | 400×720 |

| 6 | Thickness of printing plate | mm | 7.2 | 7.2 | 7.2 |

| 7 | Completemachinebafflethickness | mm | 70(y15Mnp) | 70(y15Mnp) | 70(y15Mnp) |

| 8 | Speed | Pieces/min | 0-380 | 0-280 | 0-220 |

| 9 | Printing precision | mm | Four colors ±0.3 | Four colors ±0.3 | Four colors ±0.3 |

| 10 | Die-cutting Sloting precision | mm | ±0.75 | ±0.75 | ±0.75 |

| 11 | Maximum special-shaped die-cutting plate size | mm | 900×1600 | 1200×2000 | 1600×2400 |

| 12 | Max.slotting depth | mm | 230 | 300 | 410 |

| 13 | Min.sloting interval | mm | Clock wise: 180×70×180×70 | Clock wise: 180×70×180×70 | Clock wise: 180×70×180×70 |

Corporate philosophy: Xintian is dedicated to cooperating with people from all walks of life, as well as manufacturers at home and abroad, to create a better future together!

Contact: 13699268391 E-mail: info@hb-xt.com

Dongguang Xintian Carton Machinery Manufacturing Co., Ltd. is a professional company engaged in the design and manufacture of carton machinery. Located in north China carton machinery production base — Dongguang county, it's the first manufacturer of carton machinery in Donguang county.

WeChat Code

WeChat Code WhatsApp

WhatsApp

- Copyright © 2025 Hebei Xintian Carton Machinery Manufacturing Co., Ltd. All Rights Reserved. Copyright belongs to the company.