Whole machine characteristics:

■ With the printing machine consist the last process of the carton box production line, the printing、slotting、folding、gluing and counting of the cardboard can be finished on turn, extremely simplified the carton box product processes.

■ Whole machine electric parts choice the international famous brand, good quality and steady.

■ Whole machine main driving adopted America imported synchronous belt, ensure accuracy of transmission.

■ Whole machine key moving parts adopted the imported ball screw, the quality is steady and accuracy.

■ Whole machine belt adopted high wear-resisting rubber belt, smooth operation and durable.

■ Mechanical speed: 255m/min.

■ Main motor power:11kw

■ The length of whole machine:~12m

■ Control: Three PLCS and eight servo program controls.

■ The upper and down conveyor clamping the cardboard to move forward, the cardboard inlet interval, as well as upper and down conveyor interval all adjusted electrically.

■ Paper entering section adopts spring pressure wheel to load cardboard, limit device is equipped in the pressure wheel, and the interval between the wheel and down

conveyor can be adjusted independently, make sure high paper feeding precision.

■ The middle part is equipped with secondary crease line with V shape device , which can make sure the folding precision.

■ The back part adopts vacuum suction belt to convey cardboard, in case the cardboard slide away and two folding parts are not joint together completely.

■ The back part is equipped with down folding belt, which speed is faster than the upper folding belt, the friction of the down belt movement will offset the resistance

produced by folding cardboard, to reduce problem that the two folding parts of the cardboard are not joint together completely.

■ The back part adopts rounder tower forming folding method, make the cardboard folding precision well controlled and the forming carton box with good shape.

■ The crossbeam made by thick steel plate with good Stability, the movement of the crossbeam adjusted by electrically.

Gluing part:

■ Gluing box was used elastic fixed, structure is simple and reliable,easy cleaning.

■ Gluing wheel was used stainless steel, make sure using long-term.

■ The frond of gluing wheel was used electric brush wheel,remove the waste of cardboard connection tongue, make sure connection tongue gluing well-distributed.

■ The optional system to spray on glue.

Motor part:

■ Main motor adopts variable frequency motor, synchronized with the flexo printer.

■ American Gates Timing Belt is used, with high transmission precision and low noisy.

■ Strong wind pressure device prevents the forming carton box upturned, and the wind direction can be adjusted, make sure staking tidy.

■ High speed shaping and flapping device do the last revise to the forming carton box.

Counter Ejector and strapping part:

■ Photoelectric switch counting, three units servo motors cooperated to make sure the precise counting under high speed running, accurate and reliable batch with little impact.

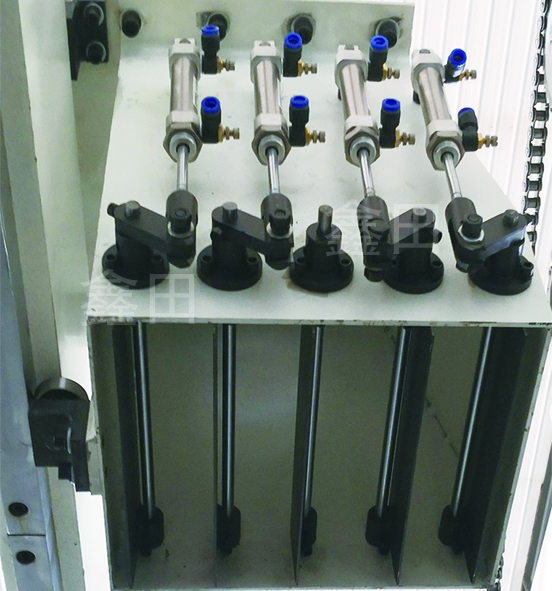

■ Pneumatic paper pushing structure to push out the counted carton box neatly.

■ Back baffle can be adjusted electrically as per the cardboard width

■ Moving parts adopts imported ball screw and linear guides with reliable stability.

■ Equipped with paper pressure device, upper and down transmission is the same speed ensures carton box neatly, the height can be adjusted electrically as per the different quantity of each pack of the carton box.

■ The left and right position of the discharge part can be adjusted, which ensures the carton box always falling down to the middle part of the machine.

|